Café Signage Updated with AGAM

The Crepeaway café is a fast-casual restaurant located in northwest Washington, D.C. The café recently decided to update its outdoor signage to a more contemporary look and useful outdoor menu. Replacing the commonplace A-board sidewalk signage and dated overhead entrance awning, the café installed a more functional and upscale signage system built from the AGAM Modular System.

This blog illustrates a before-and-after narrative showing the advantages of switching to a modular system for outdoor signage. It will also go over the benefits for both the café and sign maker responsible for its installation.

Before:

After:

The newly installed signage outlines a larger restaurant logo, enhancing brand awareness with its modern/urban appearance.

A sidewalk barrier, built with the AGAM System offers a very large menu display both sides host the logo of the brand, “Crepeaway” – offers a larger space for menu items and increases its outdoor seating capacity. The menu board also utilizes its space wisely by allowing greater exposure for those on the sidewalk with a logo on the adjacent side of the outdoor menu.

Benefits for the Café:

Crepeaway Café, located on K Street, NW serves a large variety of patrons. From busy executives to leisurely tourists from around the nation and the world.

And with the modularity of the AGAM System, the café can easily reconfigure its outdoor seating area limit.

Benefits for Sign Maker:

A sign maker who chooses to promote and sell modular system solutions instead of other commonplace signs can benefit in a number of ways.

The use of a modular system for signage can bring a consistent revenue stream with clients quick graphic changes and other market conditions that warrant consistent sign changes.

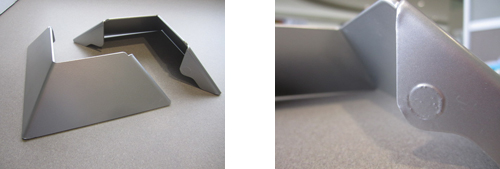

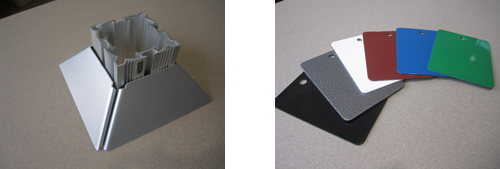

The groove that runs the length of each extrusion, a 8.5mm channel, provides substrate versatility; it can accommodate up to a 5/16″ thickness of a variety of materials: Sintra®, Gatorboard® and melamine to name a few. So depending on the project requirements, the AGAM System can accommodate those needs. And by gaining efficiencies inherent to modular systems, sign makers can standardize many sizes and materials for their end users.

System modularity offers easily customizable sizes and appearances for their clients. This is not a one-size-fits-all sign, but a true signage solution system.

Using the Crepeaway restaurant as an example, after the initial frame installation, the install time of signage is less than 10 minutes and only requires a simple hex-key. This install time reduction gives sign makers more time to find and grow existing business.

And there are no time or monies are wasted on lengthy and complicated installations and dismantles.

What Does AGAM Do?

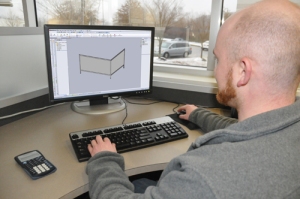

AGAM communicates directly with the sign maker. We typically receive only a sketch to go by.

All projects starts out with an AGAM project coordinator listening carefully to the sign maker and taking the project requirements and creates a solution.

Using the latest design software, AGAM creates precise 2D line drawings and sophisticated 3D renders (when needed) for your review.

All components are cut-to-size, punched, drilled and all hardware is pre-installed. Frames do not need any further fabrication and can go directly to the job site.

If you want to know more about our capabilities, feel free to call or email.

Justin Worsley

jworsley@agam.com

Multimedia Designer

AGAM

http://www.agam.com

1-800-645-0854